Cooling towers and chimneys

since 1994 up to present time we have repaired more than 750,000 m² of cooling towers and chimneys of industrial companies in Slovakia, mainly in energy industry area, paper and pulp industry, refineries and chemical industry.

— Complete deliveries of Chesterton coating material and its application on 4 cells of fan cooling towers of 1st block in Nováky Power Plant (2005)

— Water jet blasting of steel concrete cooling tower U.S. Steel Košice (2004)

— Repair of coating on pipelines and fittings on water inlet to cooling towers 1-4 in shafts of flaps in Jaslovské Bohunice Nuclear Power Plant

— Material delivery for complete rehabilitation and reconstruction of 120 m cooling towers inner and outer surface for Jaslovské Bohunice Nuclear Power Plant in 1999, 2000

— Abolition of steel chimneys — 3 pcs – U.S.Steel Košice – 2006

— Application of final coating for 3rd stage of repair of fan cooling tower block No. 1 Nováky power plant — 2006

— Chimney repair — U.S.Steel Košice – 2006

— Inspections and revisions of chimneys – U.S. Steel Košice – 2007, 2008

BENEFITS:

— Increased production efficiency

— Longer operational life of reinforced concrete structure

Floors

it is a broad area of original systems reconstruction realization and applica-tion of new floor systems. Since 1996 CHESTREAL PROGRESS a.s. company realized approx. 80,000 m2 in workshops with extreme mechanical or chemical impact.

— Building floor repair and maintenance – floor surfaces (JAVYS*, a.s. – 2006)

— Floor reconstructions in halls (potholes) (John Manville company – 2006)

— Repair of epoxy self leveling floors in technological objects in -Jaslovské Bohunice Nuclear Power Plant and Mochovce Nuclear Power Plant – 2002 -2009

— Repair of tank inner surface (JAVYS, a.s. – 2007)

— Repair and damp-proofing of floors, made of concrete blocks against rainwater in storage site of turbo-generator bulkheads of Mikšová Hydroelectric Power Plant with energy output of 93 MW (2008)

— Repair of floors and tiling (JAVYS a.s. – 2007 -2009)

— Repair of machinery room floor and repair of administrative building in Dubnica Hydroelectric Power Plant with energy output of 20 MW (2008)

— Local repairs of self leveling floors (JAVYS a.s.– 2008)

— Repair of floors in machinery room, entrance hall and mechanical workshop Kostolná Hydroelectric Power Plant with energy output of 25.5 MW (2008)

*JAVYS – Jadrová a vyraďovacia spoločnosť, a.s. (Nuclear and Decommissioning Company) was established in 1996 by merging of Vyraďovacie zariadenia (Decommissioning equipment) plant and Jaslovské Bohunice Nuclear Power Plant, 1st and 2nd block

BENEFITS:

— maintenance costs reduction

— mobile equipment protection, simplified manipulation

— improving of occupational health and safety

— improving of floor quality and service life

— ensuring of dust-free environment

— accent to human living environment protection

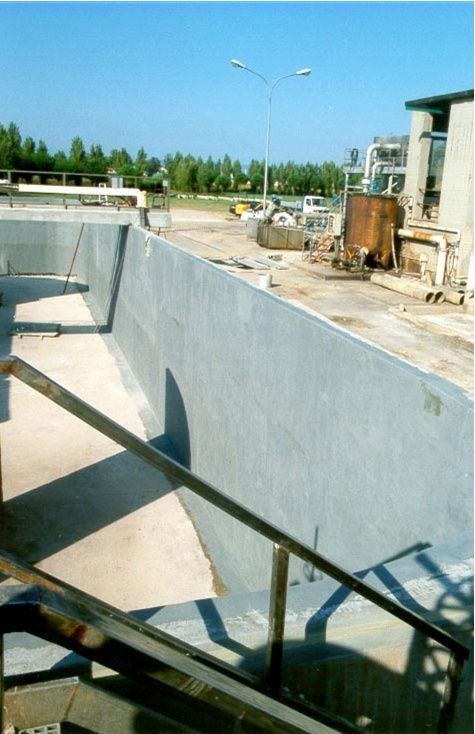

Hydroelectric Power Plants

Specificity of Hydroelectric Power Plant working environment consisting of permanent and extreme influence of water medium was the reason for establishment of independent working group within CHESTREAL PROGRESS, a.s. company. This group is focused to identification and comprehensive solution of problems coming out from the Hydroelectric Power Plant operation, especially in the area of hydro-insulations, redevelopment, reshaping and anti-cavitation, anti-abrasive and anti-fouling coatings.

— Repairs of inlet and outlet objects after emptying of derivation channel in Ladce, Ilava, Dubnica nad Váhom and Trenčín Hydroelectric Power Plants with total energy output of 61.2 MW — ensuring of channel banks water-proofing – 2006

— Coating against adherence of algae and clams Slovenský vodohospodársky podnik – significant reduction of cleaning costs, downtime reduction — 2006

— Floor repair and leakage tests in oil treatment in Orava Hydroelectric Power Plant with energy output of 21.75 MW – reduction of environmental load, reduced maintenance costs – 2006

— Reconstruction and drainage of top of inlet towers in Liptovská Mara Hydroelectric Power Plant and reconstruction of bridge from the dam to tower — Liptovská Mara Hydroelectric Power Plant with energy output of 198 MW – operative maintenance – 2006

— Repair of pits under Čierny Váh transformers with energy output of 735.2 MW – operative maintenance — 2006

— Sealing and hydro-insulation of electric channels Čierny Váh with energy output of 735 MW – ensuring of working environment water-proofness — 2006

— Ecological painting of the floor in area of Slovenské elektrárne , a.s. Kráľová Hydroelectric Power Plant with energy output of 44.8 MW – reduced maintenance costs — 2007

— Coating repair bridge between towers – inlet object of Liptovská Mara Hydroelectric Power Plant with energy output of 198 MW – operative maintenance — 2007

— Grouting in turbine cover of turbo-generator Kostolná Hydroelectric Power Plant with energy output of 25,5 MW and turbo-generator in Horná Streda Hydroelectric Power Plant with energy output of 25,5 MW – 2007

— Coating of lower constructions to prevent adhering of shells in NOSICE Hydroelectric Power Plant with energy output of 67,5 MW – increased energy output and reduced cleaning costs, shortened downtime — 2007

— Repair of inlet and outlet concrete structures at emptying of Madunice derivation channel with energy output of 43.2 MW – ensuring of channel banks damp-proofing – 2007

— Painting of turbine rotor adapter of turbo-generator Gabčíkovo Hydroelectric Power Plant with energy output of 720 MW — increased energy output, operative maintenance – 2008

— Cleaning of concrete and steel constructions of turbo-generator lower construction from shells and coating of turbo-generator structures against shell adhering inn Horná Streda Hydroelectric Power Plant with energy output of 25,5 MW — increased energy output, shortened downtime – 2008

— Reconstruction of Dobrica water reservoir in Mochovce Nuclear Power Plant – putting into service the nonfunctional water reservoir — 2008

— Repair of inlet and outlet stop logs in Nosice Hydroelectric Power Plant with energy output of 67,5 MW – energy savings – 2008

— Coating against shells repair of concrete and steel constructions of turbo-generator lower construction NOSICE Hydroelectric Power Plant with energy output of 67,5 MW – significantly reduced cleaning costs, shortened downtime

BENEFITS

— Reduced maintenance costs

— Shortened downtime

— Environmental aspect